While attending knitting festival in Blönduós last weekend, I was intrigued by the colourful leather I saw, which I believed to be snake skin. Later on, I spoke to Hjördís Þorfinnsdottir who made some colourful buttons from the leather and I found out the material was actually salmon skin. She showed me how to make a button from salmon skin step by step.

After that, we conversed and she informed me about a tannery centre in Sauðárkrókur, about 40 minutes bus ride from Blönduós, where she bought all the salmon skin displayed at the festival. After the festival ended, I decided to go to the only tannery visitor centre in Iceland, Gestastofa Sútarans in Sauðárkrókur with some Concordia students and Deborah, a residency artist/teacher from Scotland.

At the Gestastofa Sutarans, we were greeted by Marianna Margeirsdottir. She gave us a tour where the fish tanning process took place at the back of the visitor centre shop. It is also a place where staff and workers process the skin of lamb, horse and sometimes seal and other skin, according to the customers’ order.

The tanning process for fish skin takes about a month, because every fish is different – different texture, oil content, etc. The fish skin that the Gestastofa Sutarans use are wolffish, perch, salmon and cod. None of these fish are on the endangered species list.

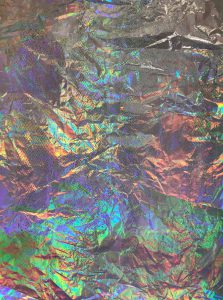

The fish skins are purchased from commercial fisheries and shipped in boxes. The combination of chemicals are used to remove all the fish oils so that there is no fish odor anymore. Through a month chemical and mechanical process, the skins are churned, soaked, fleshed, vacuum dried and dyed. The special tanning treatment prevents the fish leather from becoming stiff, once all the oil from the skin is taken out. Unfortunately, we could not see the earlier processes of tanning the skin. The following pictures are half of the processes of fish tanning that Marianna had shown us.

The fashion world is in constant flux, always changing and innovating. Within the last couple of decades, one of the most exciting trends to have emerged is the use of fish skin as leather. Fish produce a variety of textures from the vast amount of species, which has astounded leather specialists around the world.